Bill of Materials Help

Contents : Show

The process of issuing works order records results in component stock being issued and put in work in progress for the purpose of manufacturing according to works order requirements and thereby reducing the in-stock quantity accordingly. Issues are not required for kitted assemblies. However, if you have selected the Ordered or Allocated option under Works Order Movements on the Stock/BOM Options form, you can use the Issue command to issue items on the works order. Manually issued items or those issued automatically as a result of having selected the Issued option under Works Order Movements on the Stock/BOM Options, can be returned to stock using the Return command.

You can also use the Works Order Progress command for issues or returns, especially if you want to process batches or works orders simultaneously.

When you choose the Issue command, the application asks if the issues are to be made against allocations if these have already been recorded. Where this is the case, the issue also deallocates the works order quantities. The application then displays a grid form showing any allocated or unallocated works orders as appropriate. The top part of the form shows assembly information, including stock management information. In the grid are displayed the details for any existing works orders including works order reference, order date, status, reference, quantity ordered, balance to issue and issued quantity. The balance to issue is the quantity ordered less the sum of the quantities issued and made.

The following commands are available on the Action menu:

Use this command |

To |

|---|---|

Find Document |

Locate one or more documents based on a range of internal works order numbers. You specify the range on the General tab of the Find Document form and then click Display. |

Works Order Header |

Display the header details for the currently selected works order. |

Works Order Lines |

Display the line details for the currently selected works order. |

Material |

Print a materials requirements list including those items that are to be taken from stock for the works order. This might be suitable for use as a picking list for the stocked components that will be used in the manufacture of the assembly. When you select this command, the Material List form appears with the following options: Include Details (select this option if you want to include the works order details for each component); Include top level only (if the Include Details option is selected, this option can be used to indicate that the listing is to include only components at the top level. This option is only available if the Highest option is selected under Works Order Movements on the Stock/BOM Options form); Shortfall Only (select this option to print details of only those items for which there is a shortfall in meeting the assembly requirements) and Include Batch and Serial Numbers (select this option to print details of serial numbers for traceable components in the assembly). If you need to process stock records that are traceable by serial or batch numbers, refer to the Traceability Help topic for information. |

History |

Display the creation and amendment date, time and user names for the currently selected works order record. |

Reverse Selection |

Reverse which records are selected. Those already selected and deselected and vice versa. |

Edit Works Order |

Amend the currently selected works order record. You can change the manufacturing instructions. Note that when editing works order quantities, this must be a multiple of the yield quantity that can be made as specified on the assembly record. |

If a works order has been raised for a customer record, you can display the customer details using the Customer tab. You can also view or amend the works order memo using the Memo tab.

The process of returning is similar to that of issue and the same commands are available on the Action menu. You can only return works orders that have been issued in full or in part.

The Returns at Component WIP option on the Stock Control - Utilities - Set Options form affects the cost of components that are returned to stock.

Opera calculates the cost of an issue or a return to stock using the cost prices for the components plus labour costs. These are either set up on the Stock Control - Processing form or on the Stock Control - Processing - Warehouse form (if you use the multi-warehouse feature).

The WIP Value at Traceable Cost option

on the Bill

of Materials - Utilities - Set Options form determines how traceable

components are valued when they are issued from stock into work in progress

using the

Bill of Materials - Processing - Issue command and returned back into

stock using the Bill

of Materials - Processing - Return command.

This option in turn affects the valuation of an assembly when it

is made and booked into stock from the Bill

of Materials - Processing - Complete command using the

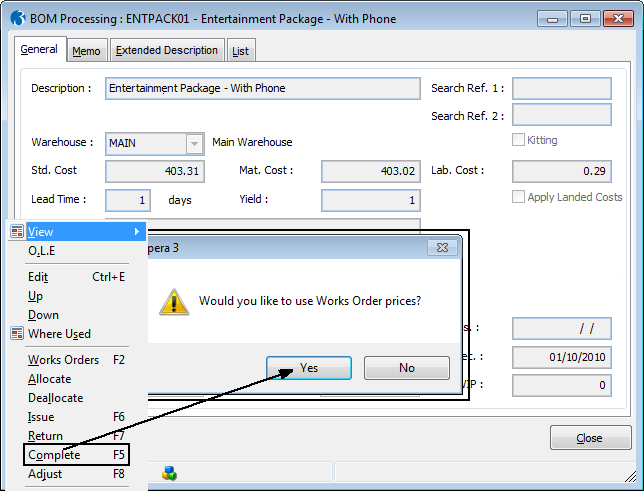

prices recorded on the works order. If the works order prices are used,

these will be based on the valuation of the traceable components used

on the assembly. Otherwise the cost of the assembly will be used.